|

|

|

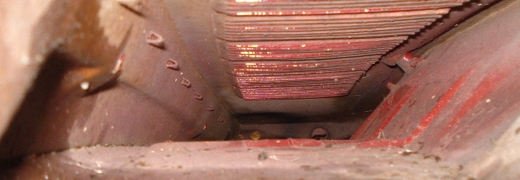

This was the junk I was able to vacuum out by reaching into the cowl from the inside.

Not a good sign.

I knew that the drain holes were clogged and every time it rained ... my feet got wet. |

|

The cowl 'hat' on the driver side was completely rotten and the side walls were in rough shape, too.

The hat on the passenger side was in surprisingly good condition. |

|

After reading a lot about possible fixes, I knew that a simple plastic patch kit alone would not work and that

the 'right' way to do it (drilling out all welds, ripping the cowl assembly apart, fixing the cowl vents and then welding the parts back together) was not an option either, because I neither had a welder nor did I want to have to get the car painted.

I call this method the 'Can opener technique' ... first, the quarter panel comes off. |

|

This exposes the outer walls of the cowl assembly. |

|

After cutting a hole into the sheet metal.... |

|

... you gain access to the cowl hats (assuming they still exist).

The one one the driver side was barely holding on and had to go. |

|

Next steps were cleaning out the cowl assembly, applying rust converter and primer. Getting to the back of the cowl was tough. |

|

As the rust on the driver side was extensive, I patched larger holes with fiberglass mats

and sealed all with epoxy.

Yes, it is messy. |

|

With the car jacked-up on the left side, the epoxy hardened,

creating a sloped and smooth surface. |

|

With this done I installed the plastic replacement 'hats'. |

|

Closing up the cowl.

|

|

This was a good time for new splash guards. The one shown on the left is the guard that sits behind the wheel. The smaller one sits in fromt of the wheel (The quarter panel is rotated 90 degrees ccw in the right shot).

|

|

No welding, no painting, no more wet feet.

Good call, Ted. |